A Skill Designer’s Need

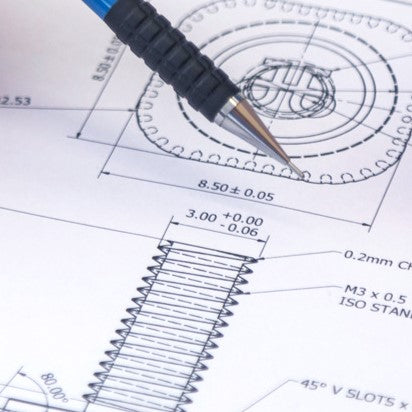

What is design for manufacturing?

It is the skill of creating your product around the understanding of how it will be manufactured. Using this knowledge, the designer comes up with creative ways to create a functional, quality and cost-effective product.

Why design for manufacturing?

A common mistake we see with a lot of new designers is not understanding the manufacturing process when creating a product. From experience, this becomes evident when the price for the new product becomes too expensive due to unconventional and complicated moulds or jigs. Another example is when the part has been designed with very high tolerances resulting in unnecessarily expensive parts. One of the most common examples is not knowing the standard sizes in a particular industry resulting in a lot of waste, for example, not knowing the dimensions of a plywood sheet.

A hidden talent in new designers.

Although in saying this, often designers who are very knowledgeable with manufacturing can have a pitfall which new designers’ triumph. Often being too rigid in manufacturing can limit the creativity of an idea. A new designer’s novelty can often lead to creative new ideas. Therefore, a designer must also still be willing to challenge conventions and think outside of the box to create new and better ways of doing things.

So how do we approach design for manufacturing?

1) We initially think of the ultimate best outcome and try as much as possible to stick with this and create innovative ways to work around it.

2) Then understanding the range of different methods for manufacturing we break the product down and assess how it can be made. Meanwhile altering the drawings to find the best solution for our product.

3) Next, we use empathy to understand it from the manufactures point of view, this helps with the cost and quality of the components. Some adjustments to the drawings are made in particular with the tolerances.

4) Additionally, if we want a feature and feel limited by the current manufacturing methods we will research and investigate new companies and methods. This is often very interesting and leads to some creative solutions.

Manufacturing processes vary for different products, so it is important to dive in and research how it’s done. Always be learning!